Thank you for stopping by our booth at

Thank you for stopping by our booth at cannex fillex 2016. Congratulations to Jeff Shortridge from Belvac Production Machinery |

|

| Torque Technologies works with plant managers, plant engineers and corporate project engineers at world-class can manufacturers, providing in-plant retrofit solutions and OEM components for can bodymakers, cuppers, shell presses and more…

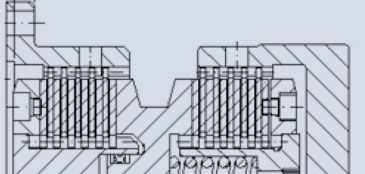

Goizper’s clutch-brakes combine faster brake reaction time and stopping time, delivering 20% higher clutch and brake torque vs. competitors. Goizper’s cam indexers provide precise spray coating delivery on machines used to spray coat can ends. Goizper’s extremely fast clutch-brake combination guarantees high levels of press uptime on cupping presses, used in the manufacture of can bodies for two-piece beverage cans. Goizper Pneumatic clutch-brakes provide high efficiency and low maintenance for can end press drive systems. |

GOIZPER’s Clutch-Brakes offer:

|

| DOWNLOAD INFORMATION ON OUR ENTIRE LINE OF GOIZPER CLUTCH-BRAKES FOR THE CANMAKING INDUSTRY... |

|

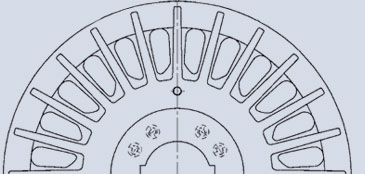

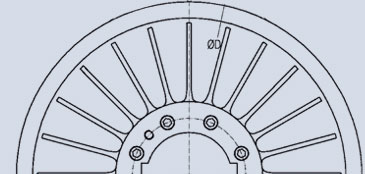

CLUTCH-BRAKES SERIES 5.7 PNEUMATIC Sizes 10, 18 and 36 are interchangable with the corresponding sizes in series 5.0. Sizes 55, 75, 76, 77 and 78 have the same diameters as their corresponding size from series 5.0 but are wider. They have very high torques and can be mounted with locking rings from both clutch and brake sides. Spacers are provided to allow lining wear compensation. DOWNLOAD NOW |

|

CLUTCH-BRAKES SERIES 5.8 PNEUMATIC One of its main characteristics is that it obtains the maximum possible torque within the dimensions of the unit, due to the fact that the piston reaches the maximum diameter. These clutch-brakes may be mounted with locking rings or keyways. DOWNLOAD NOW |

|

CLUTCH-BRAKES SERIES 6.2 HYDRAULIC |

|

|